A write protect modification for

810 disk drives

The purpose of this project is

to enhance the write-protect capabilities of the Atari 810 disk

drive. It will give you a switchable write protect tab so that you

can ensure the safety of data, make one-off file changes, or use

the B side of disks without cutting a hole.

To complete the modification you

need to be a very competent circuit builder. It is extremely easy

to make mistakes and just one slip-up could ruin your disk drive

and cost you over £60 for repair. If in doubt give up! Because of

this, I have not aimed to give step by step instructions, so if

you or a friend do not have such skills, I recommend you look at

the Autotect reviewed in PAGE 6 as an alternative.

Undertaking this product will render

the warranty of the 810 void. If you choose to do the alteration,

read this article all the way through first.

COMPONENTS REQUIRED

1 x Verostrip (Maplin FL17l)

2 x locking DPDT push switches

with single mounting bracket, screws, spacers and buttons. (Maplin

FH67X, FH75S& FL31J or Tandy 275-9401)

1 x Green LED with holder

1 x Red flashing (see text) LED

(Tandy 276-036) with holder

1 x packet of Veropins (Maplin

FL24B)

1 x 5-way socket (Maplin BH66W

& 5 x YW25C)

Wire (multicoloured)

2 x small right angle brackets

(Meccano?)

3 x bolts/nuts/washers

2 x knurled washers

There are some components worth

saying more about. Most important is the flashing red LED. Although

this will cost you about £1.10, ten times more than an ordinary

red LED, and a trip to Tandy is required (Maplin do not stock it)

it really is vital in order to keep your attention whilst write-enable

is on. Cut costs, and you could lose in the long term. Any LED holders

should do, but I don't recommend the chrome panel holders (Tandy

276-080, Maplin FM38R) because they cut the viewing angle too much.

A proper PCB plug {Maplin RK67X) could be used if you wish, but

I found Veropins quite satisfactory, and you need them anyway. Don't

cut the present cable or you will not be able to restore the 810

to its original state if you want to.

Although Maplin and Tandy have

been quoted as sources of supply, many of these components should

be available from your local electronics shop.

CONSTRUCTION

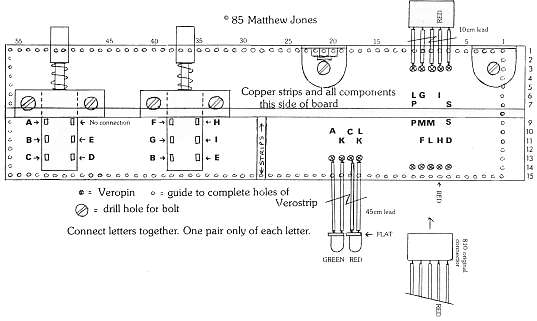

The diagrams should be sufficient

for anyone capable of building the modification, but here are some

hints you may find useful.

Make sure the 'veropin plug' is

not obstructed by wire ends around it (a file may be required),

or it may not 'make' properly and fall off later. Whatever plug

type you use, make sure only the marked wire is red, in order to

aid you in future. (The 810 pcb has the red wire marked).

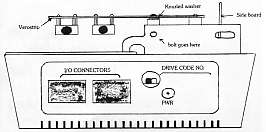

I placed two LEDs next to the BUSY

and PWR ON LEDs, but you could put them anywhere. Holes will have

to be drilled to suit your holders.

The 810 top, removed by taking

the four little discs at the top off to expose the screws, has to

be modified to expose the switches. If you look inside the top,

you will see moulded holes at the rear (opposites for the power

in and drive select switches). Cut out the two large round holes

with a sharp knife.

The switches themselves must be

mounted on the PCB using spacers. I used an old ballpoint pen barrel

cut at 7mm intervals. These are needed to position the switches

behind the holes. The switches are not soldered direct to the veroboard,

but wired together, i.e. A to A, B to B etc. There are only two

of each letter.

After you have built the board,

wired up the LEDs and connected the flying socket, you must spend

plenty of time checking your work. First, check that you have made

all the right connections as shown in the diagram. Second, very

carefully check that there are no solder splashes or strands of

wire that are, or may be in future, shorting two points. Terrible

damage can be caused by such shorts. Finally, repeat the two checks.

If you find anything wrong, correct it, and start the checks again.

You cannot be too careful.

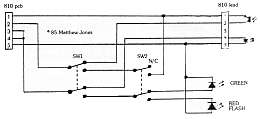

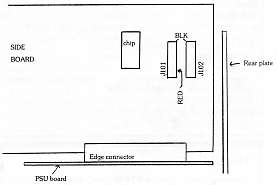

Only when you have thoroughly checked

your work should you fit it to the 810. Once you have unplugged

the power lead, you have to locate plug number J101, which is at

the back on the vertical board, and note the position of the red

wire (also marked on the PCB). Gently remove the socket, (the plug

has the pins) and fit it onto the Veropin plug, ensuring the red

wire matches. Now connect your flying socket to J101, checking that

the red wire follows through all the way from J101 to the original

socket (ignoring the break on the Verostrip).

The two right angle brackets are

each used in different ways. You will find one hole suitable for

a bolt near the centre in the metal plate at the back of the 810.

The two knurled washers are to be used with this bracket to hold

it tightly in place without pivoting. The second bracket is used

to help prevent pivoting whilst the switches are operated. It will

rest inside the metal back plate to which the other bracket is bolted.

When mounted at the back, the new board should not interfere with

any drive components. If your drive is different, do not attempt

to fit this modification, as the circuits may have changed.

8-Tect IN USE

Ensure that the fitting has been

done correctly, that you have connected the right sockets to the

right plugs and got them the right way round (use the red wire as

a guide). When all is okay, set both switches to their 'out' or

'extended' position. Leaving the 810 lid off for now, plug in the

power lead and turn on at the front. Be ready to turn off immediately

if no LEDs come on or the drive doesn't do its normal start-stop

power up. (Re-check your wiring if all is not well). Now press the

'inner' button and the green 'protected' LED should light. Press

the 'outer' button and the red LED should flash continually. Press

the 'inner' button again and only the power LED should remain on.

You must now test the write protection,

using a blank disk, DOS formatter (DOS 2 selection I) and a write

protect label. With only the ordinary LEDs on (inner button out),

the drive should act as normal obeying the write-protect tab. (If

write-protected, the drive will give error 144 when you access it

to format, otherwise it will format normally.) With a 'special'

LED lit, the drive will either be write protected (green) or unprotected

(flashing red). When all is tested and working, replace the 810's

lid. The modification is complete.

You may have thought that I have

overdone the 'make sure you check ití warnings, but I haven't. To

my cost, I hurried the 'production' version (having had a prototype

going for months) and left a minute solder splash. With a mini fireworks

display, I killed the infra-red LED and a few other parts. Fortunately

I know the 810 well and have fixed it, but as the designer can foul

up, I hope you heed my warnings and check everything thoroughly.

No responsibility is accepted by

the author, PAGE 6 Magazine or any other party for any damage that

may occur from the building of this project.

top